Fabrication Tolerances for Dimensional Variance in Sheet Metal and Machined Parts

Standard Tolerances For Stainless Steel

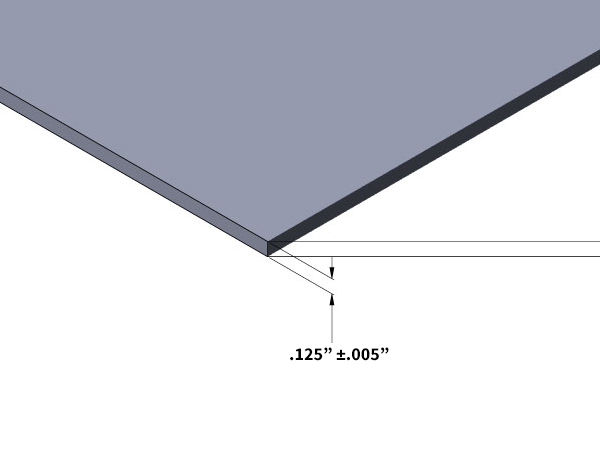

Usually, choosing material thickness is one of the first steps a designer takes when starting a project. We work with nominal thicknesses, so it's important to know the thickness tolerance on the material you chose, in order to know if the final product will be suitable for your application. It's also important when working with sheet metal that you factor in finish tolerances. For example, if you add a finish such as powdercoat, you add more thickness - this should be factored into your design at the beginning.

304 Stainless Steel (A240 TP304 2B)

| Stainless Steel | Specified Thickness | Tolerance |

|---|---|---|

| 11 Gauge | 0.120" | 3.05 mm | ± 0.005" | 0.13mm |

| 12 Gauge | 0.109” | 2.78mm | ± 0.009" | 0.23mm |

| 14 Gauge | 0.078” | 1.98mm | ± 0.007" | 0.18mm |

| 16 Gauge | 0.063” | 1.59mm | ± 0.006" | 0.15mm |

| 18 Gauge | 0.050” | 1.27mm | ± 0.005" | 0.13mm |

| 20 Gauge | 0.038” | 0.95mm | ± 0.004" | 0.10mm |

| 22 Gauge | 0.031" | 0.79 mm | ± 0.004" | 0.10mm |

| 24 Gauge | 0.025" | 0.64 mm | ± 0.003" | 0.08mm |