Fabrication Tolerances for Dimensional Variance in Sheet Metal and Machined Parts

Part Marking Tolerances

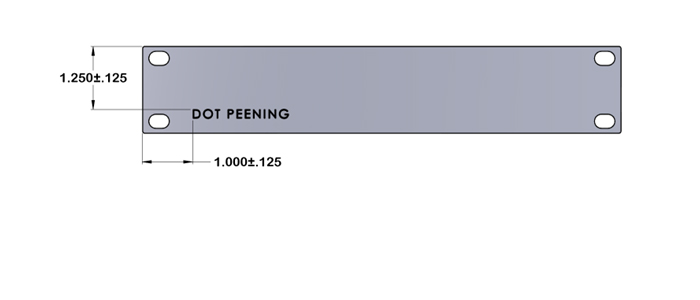

Protocase offers part marking on sheet metal enclosures and parts which can leave a dimensional variance. To avoid unnecessary re-work, you should factor in all tolerances when you design your project - including part marking. For example, dot peening positional tolerance for text is ± 0.125" (3.18mm) on the X and Y axis. Tighter tolerances are possible, but you should contact your account manager if this is necessary.

We will also do Machined Engraving (also known as Etching) at your request. This is done on our CNC mills or routers, with a standard positional CNC tolerance of ± 0.005. When determining etching on your design, depth is a factor.

| Part Marking Process | Tolerance | |

| Laser Marking | ± 0.020" | 0.508mm | |

| Engrave and Fill | ± 0.020" | 0.508mm | |

| Dot Peening positional | ± 0.125" | 3.18mm | |

| Rubber stamp | ± 0.25" | 6.35mm | |

| Etching | ± 0.005" | 0.13mm |