CNC Turning

Manufacturing Specifications and Constraints

Protocase utilizes an 8" diameter chuck with a 2" spindle bore that spins at 4,800 RPM, which is designed to hold round stock of almost any material.

Because the lathe is its own work holding, it needs enough geometry to support itself while rotating. It also needs to support the cutting forces required to cut it into shape, ergo limitations on the ratio of diameter to length are important. For example, a 1/8" diameter rod cannot be machined 12" from the chuck as the part would bend. Generally speaking, the stick out cannot exceed five times the diameter of the part. However, this rule is often broken when dealing with certain geometries.

To find out for sure if your part can be made, please contact us with any questions you may have.

The largest item we can turn is defined by the machine work envelope:

Bar Stock: 8" x 17.5" | 203.20 mm x 444.50 mm

Corner Radius:

We are able to use very small tools to make corners with a very small corner radius. Our suggested smallest insider corner radius would be no less than 0.032" (0.813mm) - for best economics.

If you need an even smaller corner radius, we stock 0.015" (0.381mm) tools. However, you may encounter depth limitations, material removal rates and increases in tool breakage rates, thus raising the cost of the part. Email info@protocase.com to discuss your specific needs.

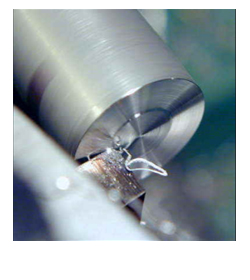

Finishing and Turning Toolmarks:

The surface finish of CNC turned parts will have visible toolmarks, due to the spinning motion produced by the CNC lathe's cutter. This is considered a turned finish.

If you require a smooth, uniform finish to your part, we recommend choosing a secondary finish such as Vibratory Finish , Media Blasting or Powdercoat.