Manufactured in 2-3 Days

Fully finished to your specifications

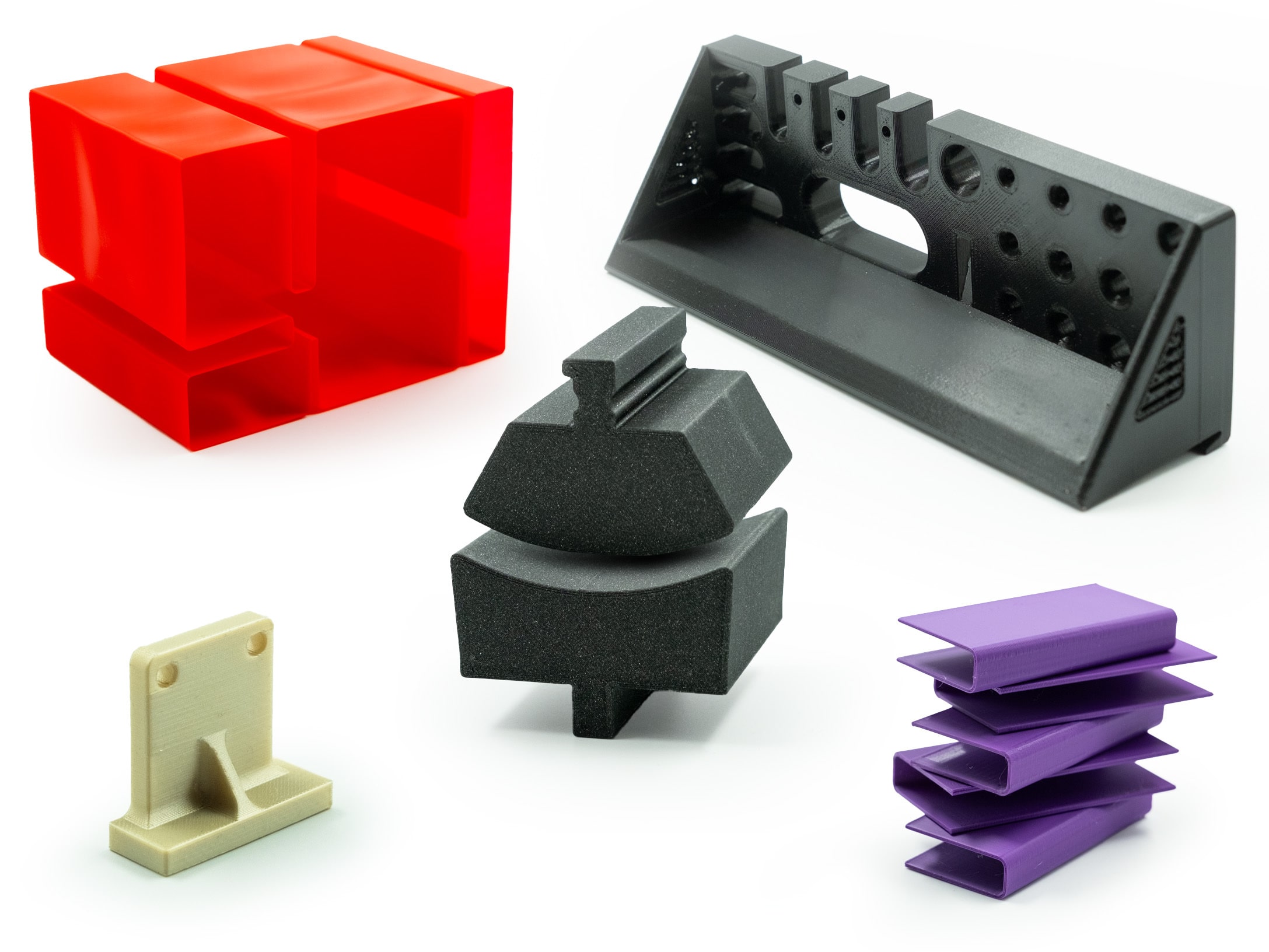

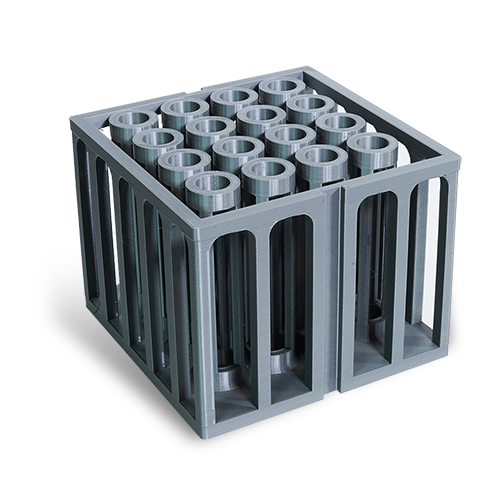

3D Printing is the process of heating a thermoplastic and printing it layer by layer to form a plastic version of a CAD model. Protocase's 3D printing uses fused deposition modelling (FDM), which involves heating the filament and then depositing it by an extrusion head onto a build platform where it cools off.

Unlike our sheet metal and CNC milling processes, 3D printing is additive. Plastic is added to the design layer by layer to allow rapid creation of prototype plastic parts and end-use products.

Manufactured in 2-3 Days

Fully finished to your specifications

No Minimum Order

Quantity 1 to high volume

Shipped Worldwide

Fast, efficient delivery via courier

14.17" x 14.17" x 14.17" (360mm x 360mm x 360mm)

PLA, PETG, ABS, ASA, PA

11.81" x 11.81" x 15.75" (300mm x 300mm x 400mm)

PEI

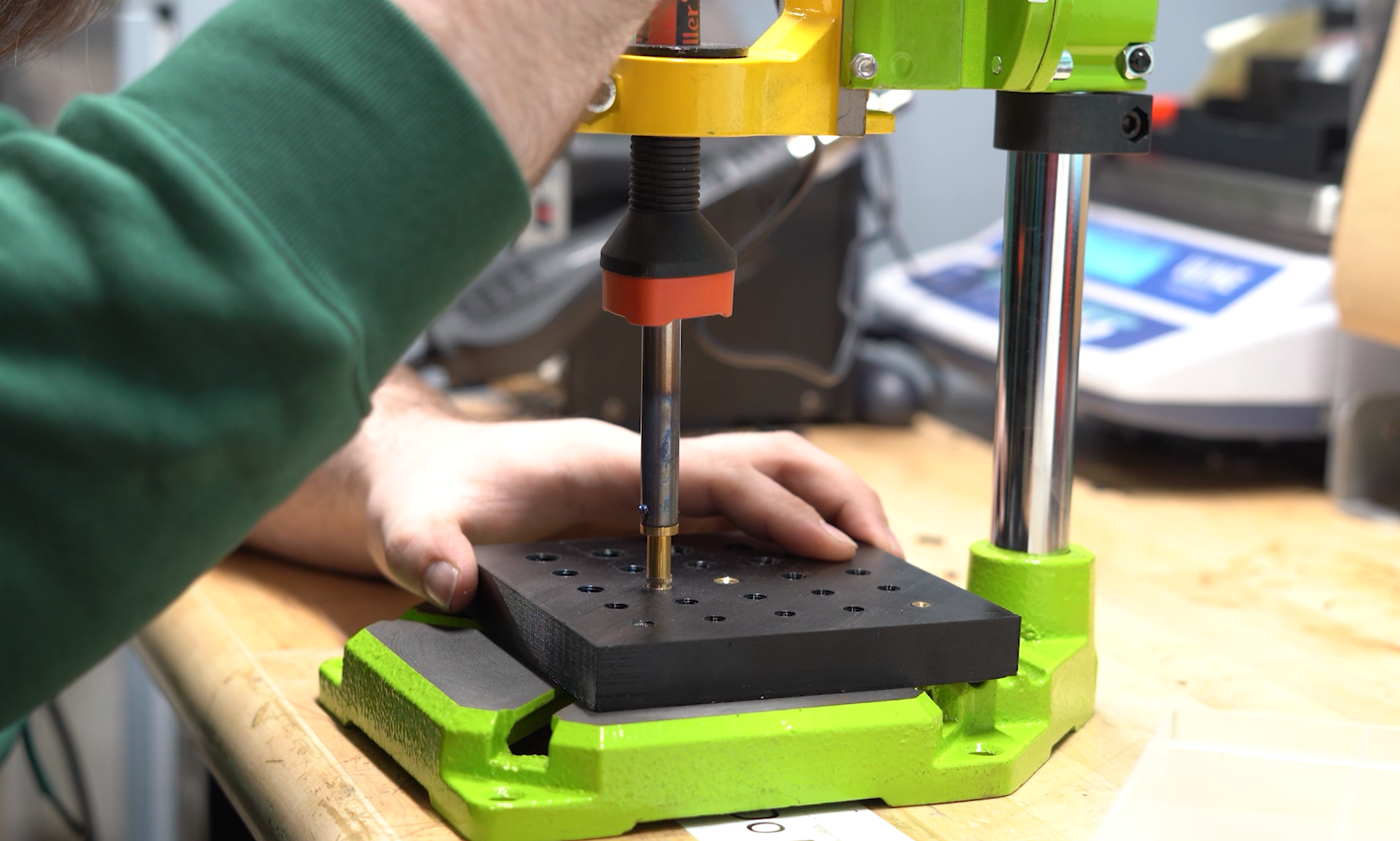

Create durable 3D-printed parts and enclosures with heat-set inserts, also known as threaded inserts. These inserts soften the surrounding material during installation, forming a strong bond between the metal insert and the thermoplastic.

Once installed, the surrounding plastic becomes stronger, ensuring a secure connection.

Protocase stocks brass heat-set inserts in both long and short options.

Learn more about heat-set inserts

Heat-Set Insert application process

We are happy to order additional filament colors based on your requirements, for an additional lead time and cost.

STL files are a widely accepted file format for 3D printed parts. If you provide an STL file for 3D printed parts, we recommend ensuring your dimensions are accurate to your design requirements, as we are currently unable to verify your part's dimensions.

We accept .sldprt or any file format that can be imported into SolidWorks. We accept any standard CAD file format, with Parasolid, STEP and SolidWorks preferred.

Our Engineering & Design Services team can provide drafting services, such as revising dimensions and making other design changes, for a reasonable design fee.

To order 3D printed parts, email your design to us or contact an Account Manager. We're here to help with all your custom manufacturing needs.

Stay Updated

Subscribe to our newsletter

to get our latest news.

Proudly Certified

© Protocase 2022 - All rights reserved.